What is a 3D Printed Model and Implants in Bone Tumors?

3D printed models and implants in bone tumor surgery refer to the use of 3D printing technology to create custom models and prosthetic implants that assist in the treatment of bone tumors. These models are based on detailed imaging (like CT scans or MRIs) of the patient’s bone structure and tumor, allowing surgeons to plan and practice the surgery with higher precision. Custom implants can also be made using 3D printing to replace or reconstruct areas of bone that are removed during tumor excision, ensuring better fit, function, and durability.

How It’s Done:

Preoperative Imaging:

- Detailed imaging studies such as CT scans or MRI are performed to get accurate, high-resolution images of the bone and the tumor. These images are critical as they provide a 3D view of the bone structure and tumor size and location.

- Using specialized software, the imaging data is converted into a 3D model. The software creates a digital model of the bone and the tumor, which can then be printed as a physical model.

- A 3D printer is used to produce a physical model of the affected bone and tumor. The model is made from biocompatible materials (like plastics or resins) and is an exact replica of the patient’s bone structure, providing a precise guide for surgeons.

- The 3D printed model allows the surgical team to plan the approach to tumor removal in detail. Surgeons can "practice" the procedure on the model, planning the most efficient route, deciding on the amount of bone to remove, and ensuring minimal damage to surrounding tissues.

- The model also helps identify any potential difficulties in the surgery, such as complex tumor locations or risks to surrounding nerves and blood vessels.

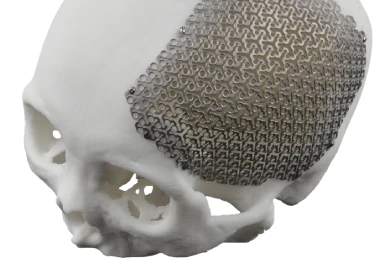

- If a significant portion of bone needs to be removed, a custom 3D printed implant is designed to replace the removed bone. This implant is typically made from biocompatible materials like titanium, which is durable and suitable for long-term use in the body.

- The custom implant is printed using the patient's specific measurements from the 3D model. This ensures a perfect fit for the patient’s bone, especially when dealing with complex or irregularly shaped bone defects.

- During surgery, the surgeon uses the 3D printed model as a guide for tumor removal, ensuring that the procedure is as accurate as possible.

- Once the tumor is excised, the custom 3D printed implant is placed in the void left by the tumor, restoring the bone’s structure and function.

- After the surgery, imaging studies may be conducted to ensure that the implant is properly aligned and integrated into the bone.

- The patient will be monitored for complications like infection, implant rejection, or bone healing.

3D Model Creation:

Surgical Planning:

Custom Implant Creation:

Surgical Procedure:

Postoperative Follow-up:

Advantages of 3D Printed Models and Implants in Bone Tumors:

Improved Surgical Precision:

- 3D printed models give surgeons a detailed, tactile representation of the patient's anatomy, enabling them to plan and execute the surgery with greater accuracy.

- Surgeons can practice the procedure on the model, reducing the risk of errors during the actual surgery.

Personalized Treatment:

- The use of patient-specific 3D models and custom implants ensures that the treatment is tailored to the individual’s unique anatomy. This leads to better functional outcomes, particularly when reconstructing large bone defects or complex tumor locations.

Enhanced Tumor Resection:

- With the ability to "pre-plan" the tumor excision on a physical model, surgeons can remove the tumor more completely, reducing the risk of leaving behind any tumor tissue, which in turn lowers the chance of recurrence.

Faster Recovery and Better Functionality:

- Custom implants that fit the patient’s anatomy perfectly reduce the need for multiple surgeries or adjustments. A good fit helps in restoring bone function more effectively, allowing for faster recovery and better post-surgical outcomes.

Reduced Surgical Time:

- Surgeons can minimize surprises during surgery since they’ve already planned the procedure with a 3D model. This can lead to a quicker surgery and lower risks associated with prolonged anesthesia or excessive bleeding.

Improved Reconstruction:

- In cases where bone removal is extensive, custom 3D printed implants can be designed to replace the lost bone. These implants are precisely made to restore the bone’s function and structure, reducing the need for more invasive or complex reconstruction procedures.

Better Visualization and Decision-Making:

- The 3D printed model provides a physical, visual representation of the tumor and bone, making it easier for the surgical team to discuss the case and make well-informed decisions. It also helps in educating the patient about their condition and the planned surgery.

Customization for Complex Cases:

- For tumors that affect complex bone structures, such as those near joints, or for patients with bone deformities, 3D printing allows the creation of implants that perfectly fit the irregular bone shapes, something that traditional, off-the- shelf implants may not be able to achieve.

- With the accurate planning that 3D models allow, surgeons may opt for less invasive approaches, which can reduce tissue damage and improve recovery times.

Minimally Invasive Approaches:

Conclusion

3D printed models and implants in bone tumor surgery offer substantial advancements in precision, personalized care, and post-surgical outcomes. By allowing surgeons to practice and plan surgeries on exact replicas of a patient’s bone structure, these technologies can improve the accuracy of tumor excision and bone reconstruction. This results in more effective treatments, reduced risk of complications, and faster recovery for patients. Additionally, custom implants ensure that the bone’s function and appearance are restored in a way that traditional surgical methods may not always achieve.